Services

Engineering design and compliance services for manufacturing solutions

Consumer Goods clients with a focus on quality leverage 3D FOREGOER’s Product Development and Engineering solutions. Our capabilities include Manufacturing, Additive Manufacturing, Engineering Automation, Fixturing, Gagging, Custom Automation, leak test. We combine our 20+ years of CAD experience mechanical engineering services, user experience and compliance to fast track innovative product development.

- Mechanical Product Design Services:

-

- Machine Design including Mechanism and Concept design

-

- 3D modelling and Detailed Engineering for Manufacturing

-

- Tools and Fixtures Design, Electrical Controls

-

- Reverse Engineering

- Mechanical product design services expertise includes

-

- Sheet Metal

-

- Plastic

-

- Tool & Fixture

-

- Rugged

- Electrical Switchgear: Design and drawing creation+

Our interdisciplinary coordination system and highly experienced Engineers and Designers have successfully supported the development of leading technology products worldwide with simplified solutions.

Prototyping:

3D printing also known as additive manufacturing is an industry 4.0 revolution. It is a versatile and rapidly evolving technology with the potential to reshape the way we design, produce, and distribute goods across industries.

Key features and advantages

Complex Geometries: 3D printing allows for the creation of complex geometries that may be impossible or difficult to achieve with traditional manufacturing methods. Innovation: 3D printing has the potential to revolutionize various industries, including aerospace, healthcare, automotive, fashion, and consumer goods, by enabling new design possibilities and manufacturing techniques. Customization, Cost-Efficiency, Reduced Material Waste, Accessibility

Innovation:

3D printing has the potential to revolutionize various industries, including

aerospace, healthcare, automotive, fashion, and consumer goods, by enabling new

design possibilities and manufacturing techniques.

Customization,

Cost-Efficiency,

Reduced Material Waste,

Accessibility

3D Scanning an Innovation Technique

- For Benchmarking your Design

- Used for Comparing Cad Data with manufactured Parts for Validating Manufacturing Precision

- Improving Quality control

- Creating 2D Drawings for Database management.

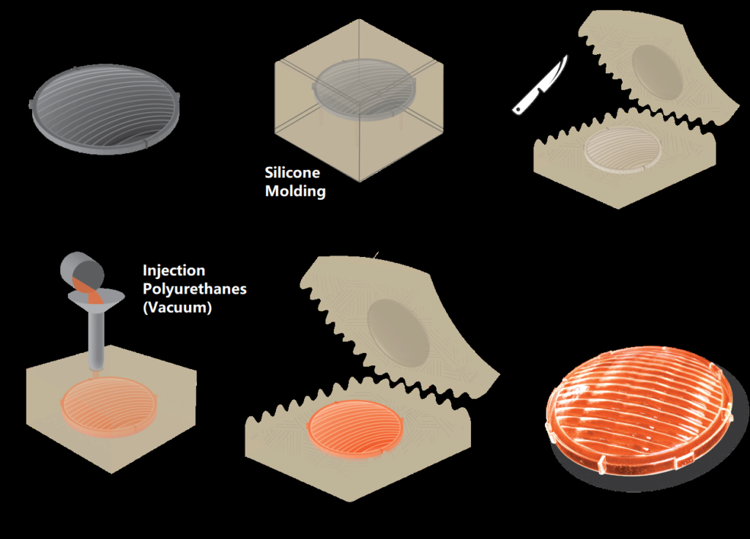

Vacuum casting

Vacuum casting, also known as silicone molding or polyurethane casting, is a versatile manufacturing process used for creating multiple copies of a prototype or part. It's particularly useful for producing small to medium-sized batches of parts with complex geometries, intricate details, and fine surface finishes. It finds applications in various industries, including automotive, aerospace, consumer goods, and medical devices.

Benefits of Vacuum Casting:

Cost-Effective for Small Batches: Vacuum casting is economical for producing small to medium-sized batches of parts compared to traditional manufacturing methods like injection molding, especially when the cost of tooling is taken into account.

Fast Turnaround Time: The process offers relatively quick turnaround times, making it suitable for rapid prototyping and short production runs.

High-Quality Parts: Vacuum casting can produce parts with excellent surface finish, intricate details, and fine features, making it ideal for creating prototypes that closely resemble the final product.

Material Variety: A wide range of materials can be used in vacuum casting, including various types of polyurethane resins with different properties such as flexibility, hardness, and color.

Complex Geometry: Vacuum casting can replicate complex geometries and intricate details of the master pattern accurately, allowing for the production of highly detailed parts.