Case Study

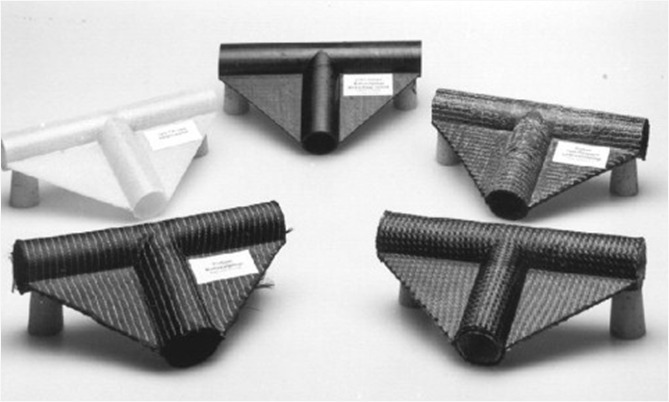

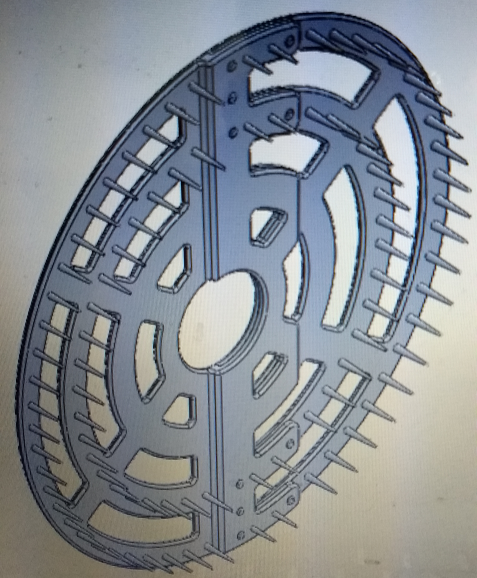

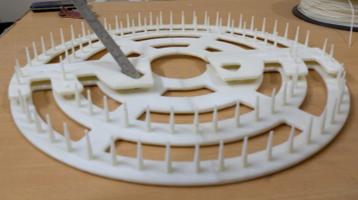

Case Study:- 3D Printed Die Mold for Carbon Fiber Preform For composite material Part Building DRDO Labs

PROBLEM STATEMENT

Die or Mold for Building Carbon Fiber perform which should be cost effective and Risk free

Project Scope:- Design Development of Core & Cavity to suit printing /Additive Mfg and making 3D printing Models.

Deliverable:- CAD Design & 3D Printed(plastic) Die Cavity and Core of Mold for stitching Carbon Fiber perform.

Applications:- This Carbon Fiber perform is used as reinforcement in silicone Carbide composite material build with chemical Vapour Depositions for testing and validations of material in Defence Systems.

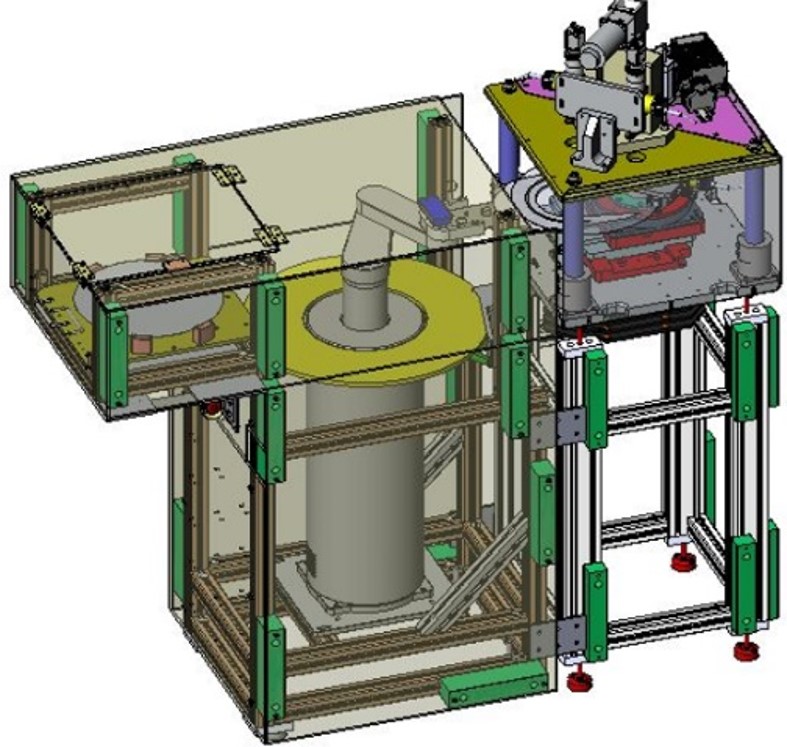

Wafer Translator Aligning tool – Probe card application Semiconductor clean room equipment Design

PROBLEM STATEMENT

Manual dipping process to automated dipping solution.

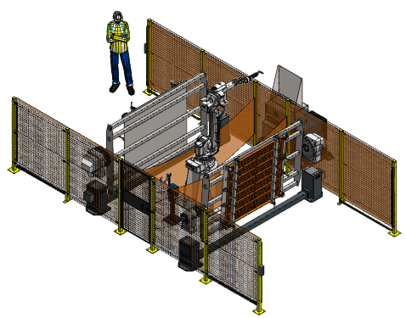

Project Scope:- Design Development of Gantry Systems and End effector.

Deliverable:- CAD Design and 2D detailed drawing & Prototype systems

Applications:-

This system used in Semiconductor application. Manually loading a Translator on

the loading station. The robot could transfer the Translator to chamber aligning

stage X-Y axis.

The stage above there’s linear screw mechanism for Z-axis vertical aligning.

Which’s pneumatic holding of chucking pads.

PROBLEM STATEMENT

Cost reduction instead of Probe card systems

Project Scope:- Design Development of Wafter and Translator aligning systems.

Deliverable:- CAD Design and 2D detailed drawing & Prototype systems

Applications:-

This system used in Semiconductor application. Onsite field study and process

observation taken Concept design for pick and place of linear arrangement

Various picking arrangement Gantry systems design for such a long length "Z"

axis movement concept for Vertical axis.

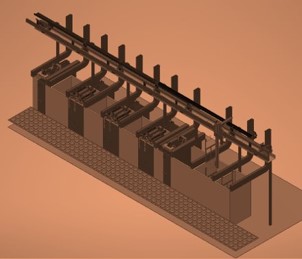

PROBLEM STATEMENT

Magnet pole checking in robotic station

Project Scope:- Design Development of Magazine magnet filling station.

Deliverable:- CAD Design and 2D detailed drawing.

Applications:- This system used in Assembly line application. In between dial 1 to dial 2 to there is magnetic station, There each solenoid valve will fill with 4 magnates. Here robot will place the solenoid valve in fixture magnets will be there in crate. The crate will with IAI with control speed and distance y-axis smc cylinder will move the magnet from the crate to fill the solenoid valve.

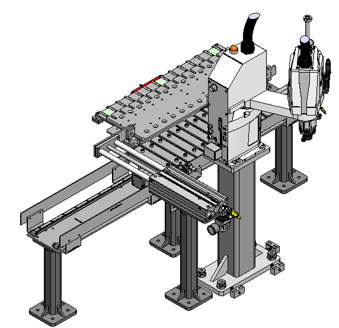

PROBLEM STATEMENT

Welding cell automation station instead of manual welding

Project Scope:- Design Development of Welding station developing.

Deliverable:- CAD Design and 2D detailed drawing.

Applications:-

This system used in welding cell application. Design of welding base part, to

connecting head and tail stacks.

Welding base structure is rigidity and torch accessing clearance. Various

concepts for fixture plate designing. Fixture plate locating and locking.

PROBLEM STATEMENT

Legacy conversion, 2D data files to conversing 3D model

Project Scope:- Design of Part and Assembly modelling.

Deliverable:- CAD Design, Part and Assembly model.

Applications:- This is Special purpose machine old drawings to regenerate the model. Basically, Data controlling purpose customer required these files.

Design / Development , Prototyping for Real

Time Testing -Indian Railways

Computer Aided Design (CAD)

Real Time Testing on tension lines

3D Printed Model /Rapid Prototype